Welcome to the world of Westtech!

We do more than develop and manufacture robust forestry and landscaping equipment.

Individual customer service is our primary factor of success. Every product range is developed by Westtech’s experienced team of engineers, always in close collaboration with you – our customers. It is our goal to continuously optimise the product range according to customer requirements and the application areas.

Made in Austria

Austrian quality products by Westtech. Development and production from one source guarantee the highest quality standards and the associated long service life of the products.

NEXT TECH

Become familiar with the reliability of Woodcracker, Mowblower and Mulcher! Westtech products set themselves apart through innovative technology. For us, NEXT TECH means, to be a step ahead.

Biomass logistics

With our Woodcracker product range and our know-how, we provide support to you throughout the entire biomass logistics chain.

Harvest > Storage > Transport > Chipping > Recycling

Westtech academy

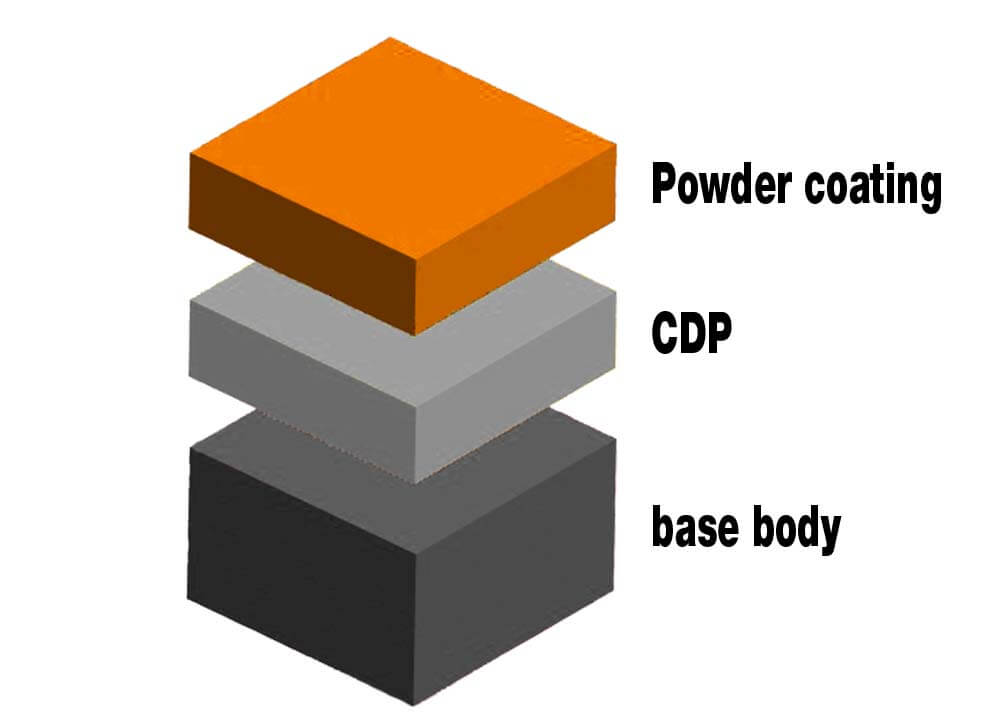

Cataphoretic dip priming and powder coating

The company Pöttinger in Grieskirchen executes the machine piece’s dip priming and powder coating for WESTTECH.

The process involves the following steps:

- Surface preparation: In this process the surface is cleaned and the edges rounded off.

- Pretreatment: The automatic handling system conveys the units through the baths.

- Priming: This involves a 3-zone CDP (Cataphoretic Dip Priming) process using water-based paint, as used throughout the automotive industry. The advantage of this type of priming system is its excellent corrosion protection and uniform thickness of each coat right into every cavity.

- Baking: Optimum adhesion of the primer to the workpiece is ensured by baking at 200°C.

- Top Coat: The top coat is applied using powder coating.

- Baking: The powder coating finish needs to be baked at about 200°C to achieve the best possible quality.

The advantages for the cataphoretic dip priming are perfectly clear:

- excellent corrosion protection

- uniform thickness of each coat

- every cavity gets coated completely

- very eco-friendly due to very little solvents

The outstanding resiliency and durability are marks of this coating process. No cracks will generate in the coating even with stress due to shock or deformation. Likewise, the method is one of the most eco-friendly coating methods. The production and processing happen without any solvent. Westtech uses this coating method with all their machines to achieve the highest possible longevity.

Multigrip and Autospeed

The so-called Multigrip is composed of a big hydraulic block inside the Woodcracker® machine and regulates with just one double-acting hydraulic connection the gripper’s opening, closing and the cutting unit. This regulation is achieved by a pressure control sequence, which provides the gripper and the cutting unit with oil. While closing the machine the gripper has the higher priority, when opening the machine it’s the other way round. Thanks to this feature working with the Woodcracker® C is much safer, due to the tree’s safe grip while cutting. The Multigrip enables very high hydraulic performance, depending on the carrier vehicle between 100 and 200 l/mins.

The hydraulic block has a default pressure protection at the input side which is sealed, additionally.

Optional can “Autospeed” be built in at an excavator’s lower hydraulic power. Autospeed enables 30% higher speed when closing the cutting unit during an empty run or with lower load.

The saw unit

The CS serie’s saw unit – innovative technology at its finest

The CS series by Westtech, a forestry machine producer in Upper Austria, contains four different grip saws up until now. The Woodcracker® CS, CS smart and CS compact got developed for rigid mounting and especially for safety tree fellings. The Woodcracker® CS crane, on the other hand, is cardanic mounted.

The machine’s centerpiece is the saw unit with the chain saw.

This component sets itself apart by a lot of outstanding features.

1) actively suspended saw unit

2) automatic chain tensioner

3) automatic grease lubrication

4) easy chain and bar maintenance

1) actively suspended saw unit

The saw unit has a swinging chassis with active suspension and can be tilted. The suspension prevents clamping of the saw even at high-risk force and the tilt function ensures a safe retracting of the saw, even with a positional change of the cut material.

2) automatic chain tensioner

The automatic chain tensioner keeps the chain under the right tension – no matter if the machine just gets started or if it’s already operating for a while. The working process doesn’t have to pause to mount a jumped off chain again.

3) automatic grease lubrication (Woodcracker® CS, CS smart and CS compact)

The chain gets supplied with grease by an automatic lubrication pump. With every cutting operation a defined amount of grease gets pressed into the saw bar.

Compared to an oil lubrication, there is no oil fogging and therefore no contamination of the driver cabin windscreen. Additionally grease lubrication is long-lasting and economical.

4) easy chain and bar maintenance

The saw bar is easily accessible via the machine’s maintenance position. If it is necessary to change the saw chain or the saw bar, these processes are a piece of cake.

Mounting options Woodcracker® C

WESTTECH offers four mounting options for the treeshear Woodcracker® C.

1) Rigid mounting

- Using slewing drive of excavator

2) Option: cylinder slewing system

- 2 x 48°

- Low-maintenance

3) Option: Tiltator

- Endlessly rotatable (360°)

- Using a tiltator, the gripper can be turned around and used to sort lumber

4) Option: Power-Tiltator

- During tree removal, the Power Tiltator provides more strength by the means of double torque at the same speed.